Safety First

We train our teams to meet or exceed the safety protocols established by your site.

We train our teams to meet or exceed the safety protocols established by your site.

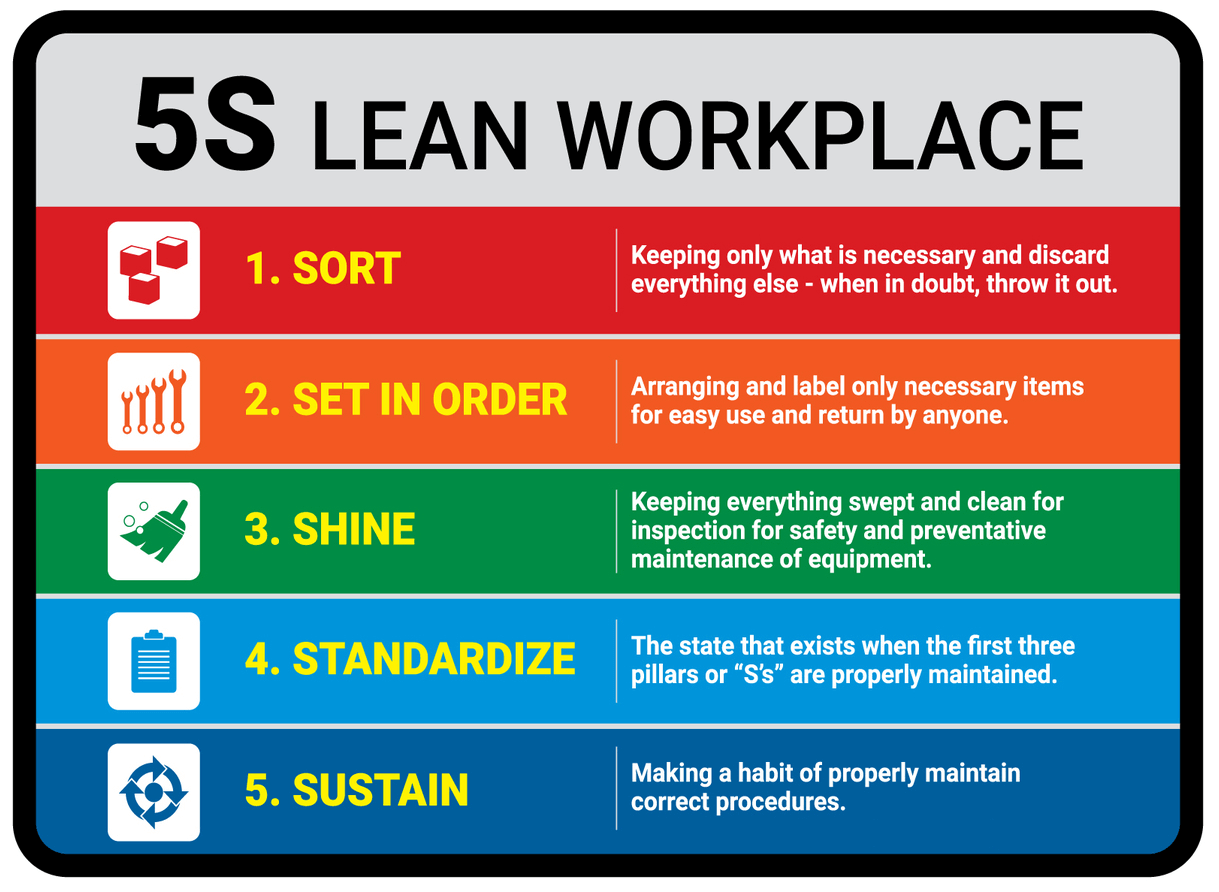

We practice 5S Lean in the workplace to exceed customer quality standards for plant operations.

Program: This system consists of open, frame-mounted platforms which the client configures for multiple reaction pathways. It’s capable of synthesizing theoretical or practical toxic and hazardous chemicals and simulants.

NRT provides planning, preventative maintenance, repairs, quality control checks, and safety inspections at regular intervals. Our team also helps to continually improve the program’s quality and lean operations by recording all repair and maintenance information to a database. We carefully track this data to plan for parts inventory and optimize the maintenance schedule—both of which reduce system downtime.

A Note About Safety: We perform all work following strict OSHA standards and guidelines. At minimum, all NRT staff are trained and certified for hazardous waste management, chemical safety protocols, PPE, lockout/tagout procedures, and NFPA-70 standards for electrical safety.

We’d like to hear about your program’s maintenance needs. Call us today at 435-830-1143.